Processing steps

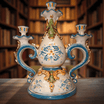

The manufacturing process that leads to the creation of our ceramics is divided into six important phases: Turning, Drying, first firing, Glazing, Decoration and Aging .

For each of these phases we dedicate the utmost care to every detail so that the final product is the result of a unique, inimitable and unaltered work over time.

Turning and Forming

The first phase of Majolica processing consists in giving shape to our creations and this occurs through two important paths: Turning and Modelling.

Drying and 1st cooking

The second phase is drying in which our products are subjected to slow, gradual and natural drying without temperature changes, in order to expel all the water contained in the clay. This phase will be followed by the first cooking with ovens that reach temperatures estimated at approximately 1000° for 13 hours.

Enamelling

After the first firing there is enamelling, in which the products acquire a totally white color based on oxides and kaolin; thus ready to pass into the hands of decorators who will give color and style to the creations.

The colors used in our laboratories are designed and studied according to color shades and effects.

Decoration

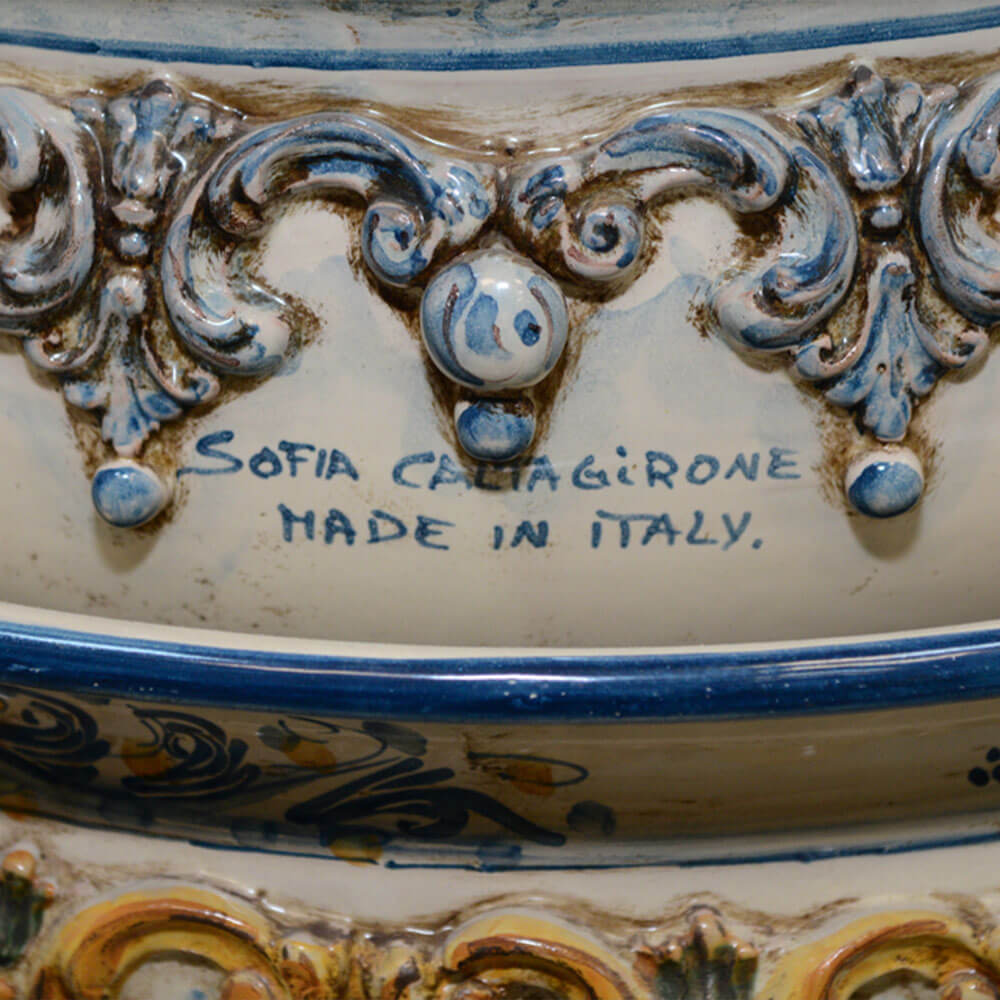

The Decorative phase is characterized by giving style to our creations with shades of colors designed and created by us in the laboratory. Colors, shapes and style are the goal to make our Sofia brand personal.

2nd Cooking and aging

The second cooking is the most important phase where everything cooked at the established temperatures acquires shine and brightness, thus enhancing shapes and colors. Through particular techniques, the chiaroscuro is highlighted on the crystallized effect of the majolica, inspired by the great master CARAVAGGIO.

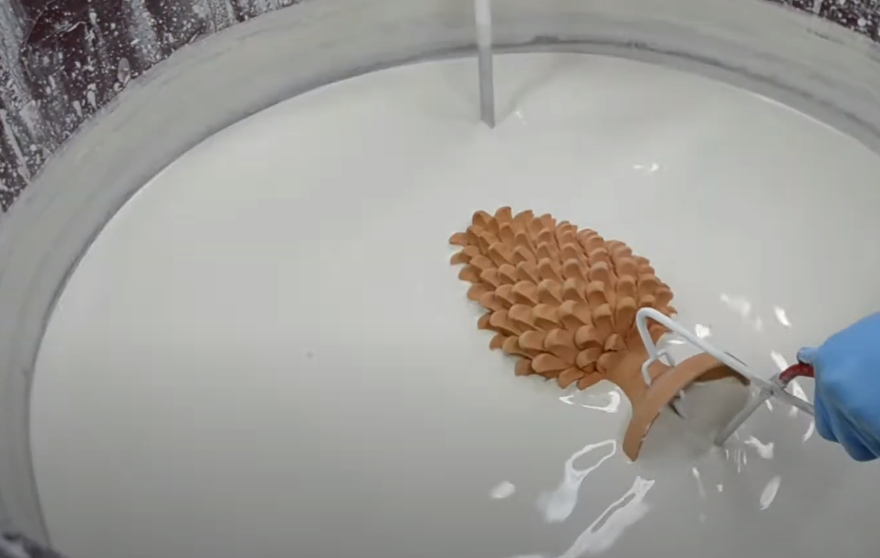

Pine cone processing

A small extract from the processing of our artisanal pine cone. Each segment is applied by hand on a base made on the lathe.

The main feature of purchasing a non-industrial product is precisely this: owning a unique product .

Watch the full video